Scope/Purpose of the Position

The Quality Assurance Technician is a critical part of the plants food safety and quality system who is responsible for monitoring, documenting, and enforcing policies as well as training key team members and taking critical corrective action when required.

The technician role is a hands on, highly interactive role in a fast-paced, ever-changing production environment. The ability to quickly assess risk, lead a team to a decision point, and ensure plans are executed are critical skills required to perform this role.

Major Responsibilities and Essential Functions:

- Monitor process controls (CCP’s, Allergen Control, Foreign Material Control, Labeling Requirements, Package Integrity, Product Specifications) to ensure adherence to all food safety and quality programs

- Perform sample collection as required for microbiological or chemical testing (APC, Yeast & Mold, Water Activity, Moisture)

- Perform product sampling and analysis to monitor product texture and shelf-life

- Troubleshoot and take appropriate corrective action when deviations occur

- Document, monitor, and analyze data to drive continuous improvement

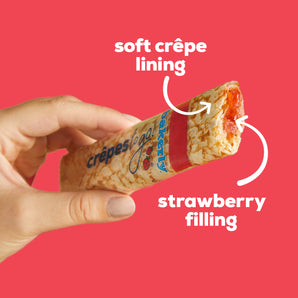

· Maintain a comprehensive understanding of all products manufactured by the plant as well as the raw materials, packaging materials, and operations required in the manufacturing process

- Perform quality audits (AQL’s) to ensure product meets specification

- Investigate customer feedback and internal incidents and provide responses in a timely manner

- Monitor employees for proper work conduct including but not limited to GMP’s, SOP’s, and SSOP’s

- Review paperwork for accuracy and compliance to all food safety and quality programs

- Routinely interact with plant management teams (Production, Maintenance, Supply Chain)

- Review monthly goals and continuous improvement projects with Quality Assurance Manager

- Perform other duties and as assigned by the Quality Assurance Manager.

Job Qualification Requirements:

Bachelor’s degree in a science discipline or 1-year of experience in a Quality assurance role in a food manufacturing facility

- Ability to assess risk and make decisions under pressure in a fast-paced production environment

- Exceptional communication skills

- Ability to effectively present information and respond to questions from groups of managers and/or coworkers

- Ability to work both independently with minimal supervision and in a team environment

- Critical thinking skills

- Ability to multitask and prioritize

- Ability to read and interpret data and related documentation

- Basic mathematical (addition, division, multiplication, percentages) and computer skills (Email, Excel, Word, PowerPoint)

- Excellent time management skills

- Excellent attendance and punctuality

Ability to work on your feet in a warm and cold environment

We are an equal opportunity employer and considers all qualified applicants equally without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, veteran status, or disability status.

Bakerly Barn provided the following inclusive hiring information:

We are an equal opportunity employer and considers all qualified applicants equally without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, veteran status, or disability status.

All employees are REQUIRED to wear a mask at this time

Salary: $38,000 per year